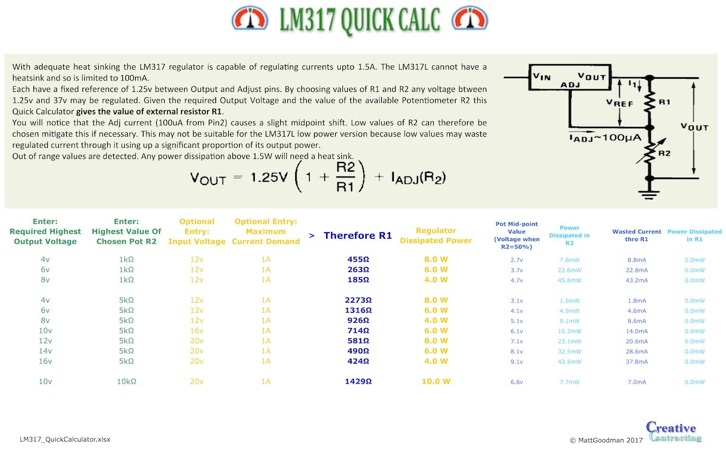

G4. Calculate Regulator Resistor Values

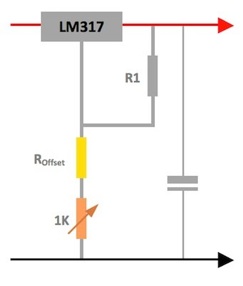

We now have two simultaneous equations. The first one can be simplified to:

ROffset = R1 x (4.3/1.25 - 1) = R1 x 2.44

If we now substitute this into second one we can solve for R1:

1.25 x (1 + (R1 x 2.44 + 1000) / R1) = 9v = 1.25 x (1 + 2.44 + 1000 / R1) = 4.3 + 1250 / R1 = 9

Subtracting 4.3 from both sides we get:

1250 / R1 = 9 - 4.3 = 4.7

Rearranging to solve for R1 we get:

R1 = 1250 / 4.7 = 266 Ω

If we now substitute this answer into the first equation we get

ROffset = 266 x 2.44 = 650 Ω

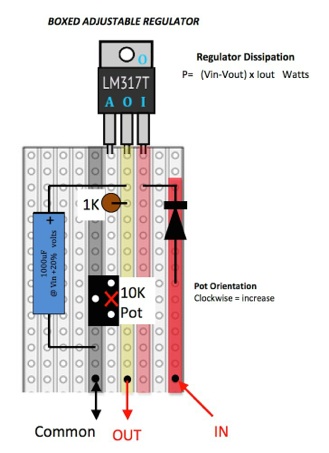

The box above facilitates this process quickly with real components.